Progress on Altar I has been steady since the previous report. A new batch of fully fitted and featured prototypes have been created, near-final PCBs have been delivered and tested thoroughly, packaging design is in flight, and firmware development has progressed smoothly. Altar I gets closer to reality every day.

PCB design + fabrication

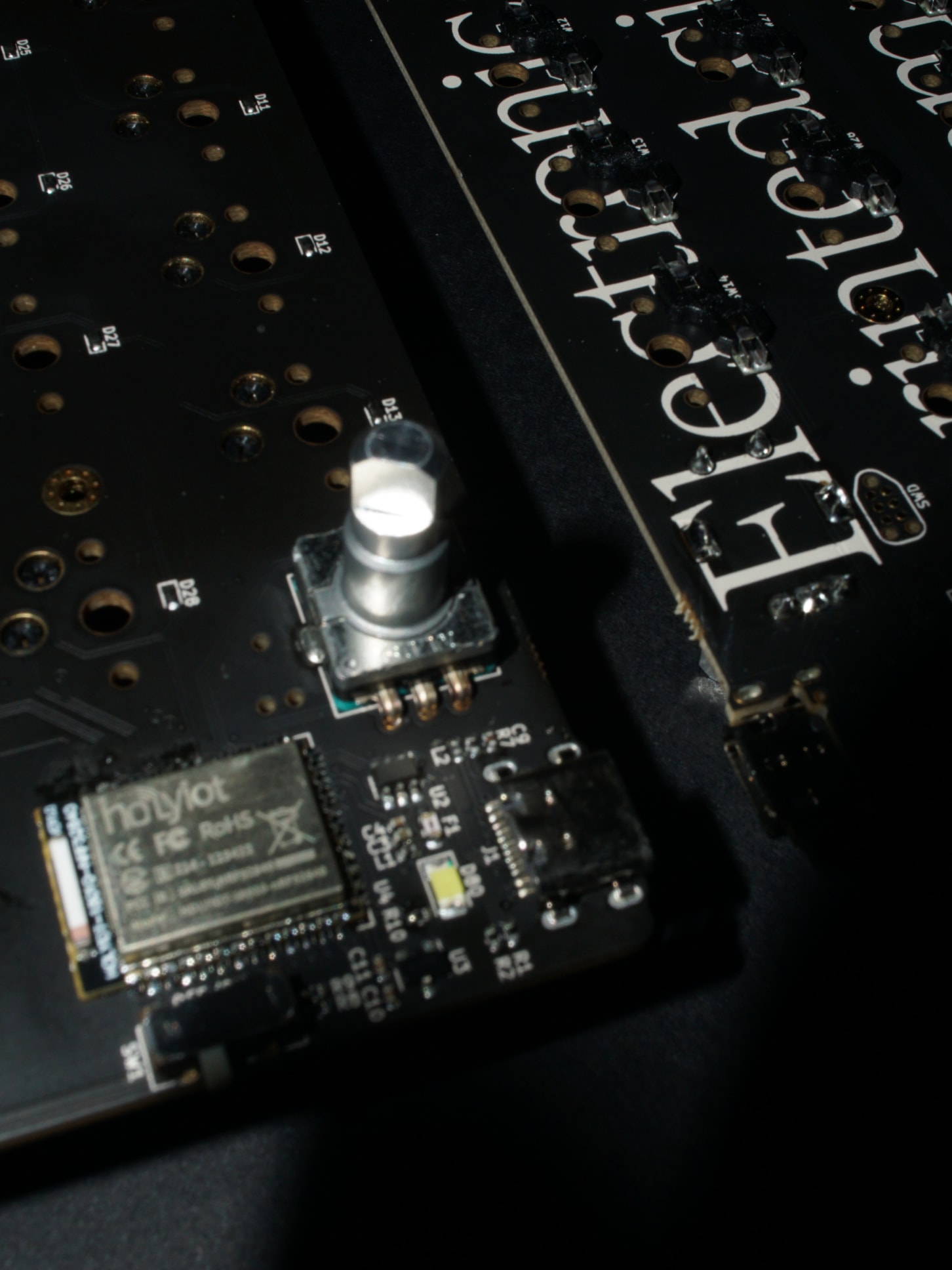

PCBs (featuring the hot swap capabilities detailed in the previous report) have arrived from our PCB fabrication facility and undergone testing.

Special care was taken to design the typography on the back of the board, despite the fact almost nobody will see it. As Steve Jobs's father said to him:

"You gotta make the back of the fence — that nobody will see — just as good looking as the front of the fence. Even though nobody will see it, you will know, and that will show that you’re dedicated to making something perfect."

PCB testing has gone well. All components line up with bodywork, the battery works as anticipated, and hot swap functionality is smooth. However one minor change will be made: The battery connector will be moved to the underside of the PCB (currently it is on the topside) to enable easier assembly and replacement.

Once this is done, work on the PCB can be considered complete for now.

New fully featured prototypes

A new round of prototypes have been assembled to test-fit all components. Everything sits together well and the following issues have been addressed:

- The USB cutout now lines up better within the monobody enclosure

- Stabilisers have improved fit and response

- Raised keys have had their interior redesigned to make injection moulding easier

The next step is to move on to placing larger orders from our suppliers.

Firmware update

Firmware development, which began shortly after the previous progress update, is mostly complete. There is one remaining bug however. After fixing that, we can move on to "nice to have" and quality of life firmware enhancements.

Packaging

We want the packaging of Altar I to reflect its sustainability and environmental goals. To that end, we've worked hard to eliminate all plastic from Altar I packaging.

Altar I will be enclosed in a clamshell composed of sugarcane pulp (also known as bagasse), which is fully biodegradable and recyclable. The design of this clamshell has been tweaked and is now complete. Final samples of the clamshell will arrive in the next week or so.

A paper wrap has been designed to cover and protect Altar I when in transit. Being paper, it is easily recyclable. Samples for this wrap are also anticipated to arrive in the next week or so.

A custom corrugated shipping box has been designed and samples received. Designing a custom box, while significantly more expensive than using an off-the-shelf box, allows us to minimise shipping volume and weight, and is therefore less wasteful to ship.

What's next

We are now in a position to place larger orders of finished parts from our main manufacturing partners. Before we do that we will create cosmetic surface acceptability criteria — which tells vendors about the high cosmetic standards demanded by Altar I.

Moulds for injection moulding will be created by our main manufacturing partner, and samples provided from these moulds. This is a critical milestone for Altar I, and we expect to go through several rounds of iteration before we're happy with them.

The battery connector will be moved to the topside of the PCB, and we'll also fix the last firmware bug.