Progress has been steady on Altar I since the last progress report. Injection moulding samples have been created, batteries and packaging have been delivered, bare PCBs have been manufactured, firmware has been tweaked, and the Altar I field manual has been written.

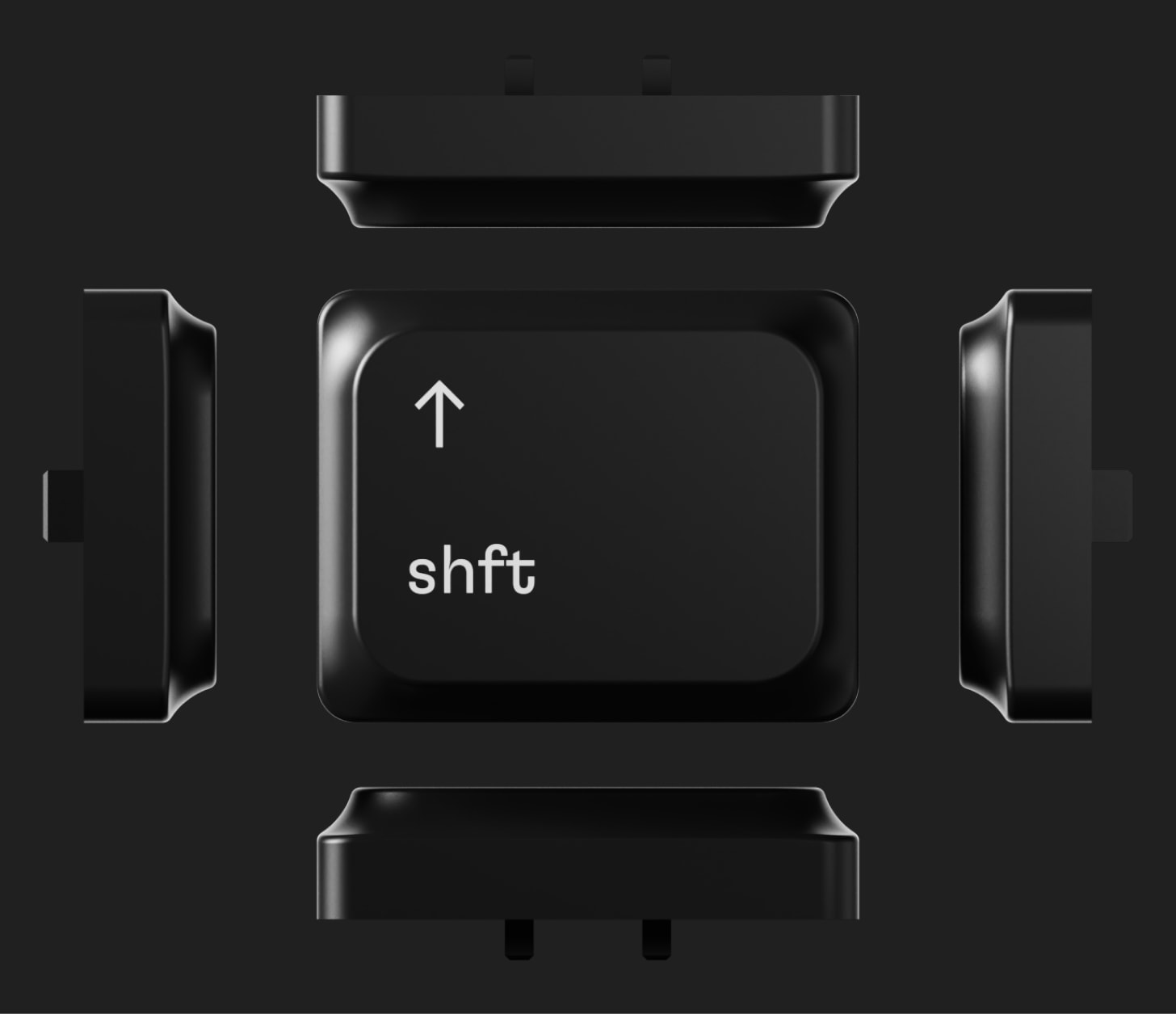

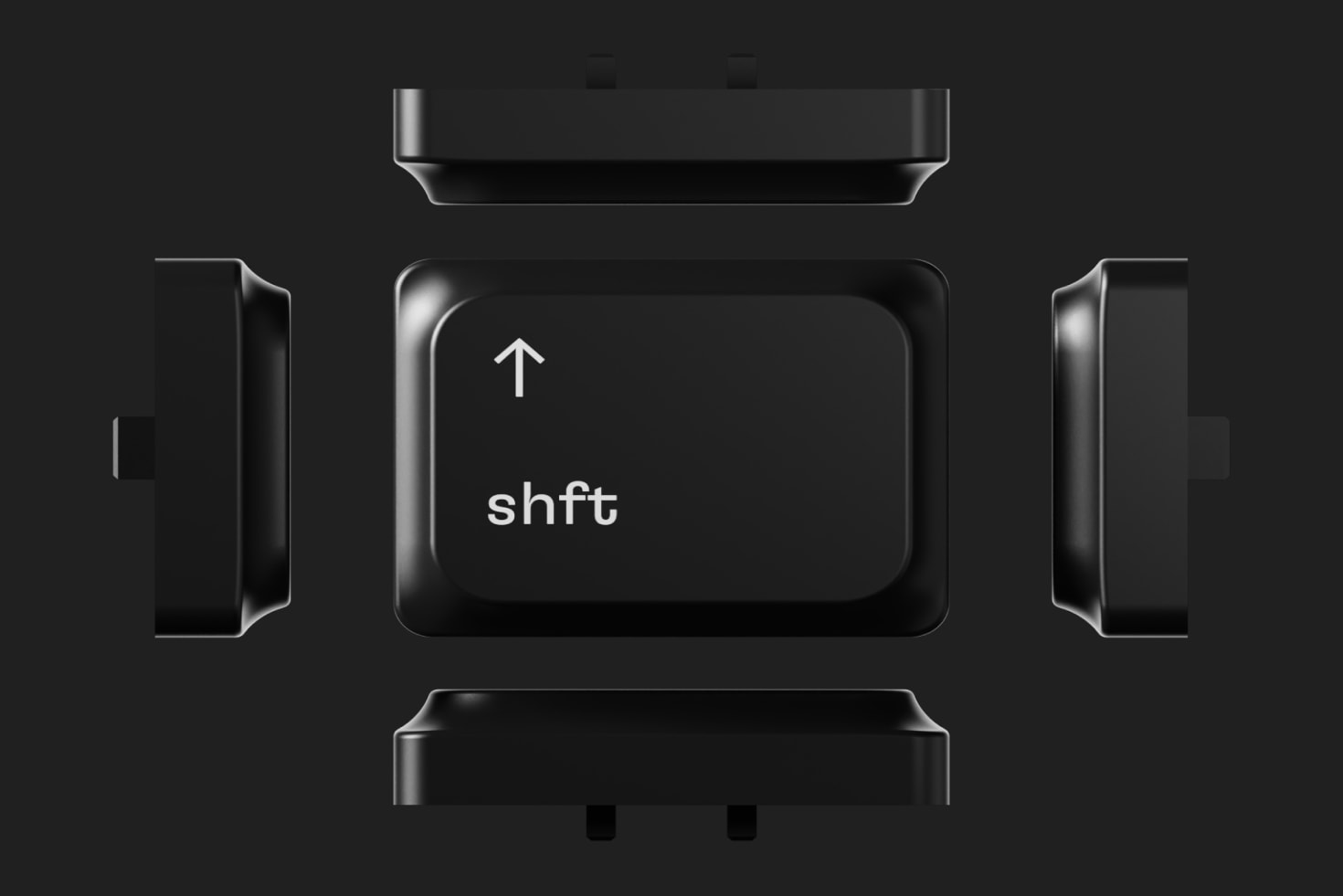

Injection moulding samples

The first round of injection moulding samples, known as "T1" samples, have been created. Overall these met expectations however two minor adjustments are being made:

- Raised keycaps will be made slightly thicker (0.3mm) to prevent shrink marks appearing. This thickness is being added to the underside of the keycap so it will not be visible to the user

- Keycap stems will be made fractionally thinner (~0.05mm) to improve fitting with switches. The samples produced were slightly too tight fitting when mated with their switches, and this will alleviate the issue.

Note the surface finish shown is not representative, and will be dialled in for the next round of samples.

Silicone samples (for the feet and the knob insert) are currently being produced.

New arrivals

Batteries, shipping boxes, and paper wraps have all arrived at the assembly facility. Clamshell packaging will land at their destination port in the coming days.

PCBs

Bare PCBs have been manufactured, and several fully finished boards have been tested successfully. The remaining bare PCBs will now be assembled with their electronic components.

Firmware

Additional small firmware improvements have been made. This time the deep sleep setting of Altar I has been changed from 2 hours to 15 minutes. This has again significantly improved battery life and not had any tangible impact on the user experience.

During deep sleep, Altar I disconnects from Bluetooth® and enters a low power state. Pressing any key wakes up Altar I and automatically reconnects to Bluetooth® in around 2 or 3 seconds.

Field manual

The Altar I field manual — an online handbook for Altar I — has been written and is currently being finalised. We hope to share a preview of this in the next progress report.

What's next

Focus remains on injection moulded parts: a new round of refined samples is now being created, in addition to silicone samples, and testing keycap printing. Finished PCBs will ship in 2-3 weeks, and the last of the packaging will arrive around the same time. A pilot assembly programme will be run in early January and will be used to produce a small number of fully finished devices.